ABB ELECTRIC MOTOR

Price 5000 INR/ Piece

MOQ : 05 Pieces

ABB ELECTRIC MOTOR Specification

- Bearing Type

- Deep Groove Ball Bearing

- Sealed Type

- Dust Proof

- Poles Number

- 4

- Motor Type

- Squirrel Cage Induction Motor

- Starting Type

- DOL

- Efficacy

- IE2

- Power Rating

- 3.7 kW

- Cooling Method

- Fan Cooled

- Standard

- IS 325

- Voltage

- 415 V

- Horse Power

- 5 HP

- Noise Level

- Less than 70 dB

- Rated Voltage

- 415 V

- Features

- Low Maintenance, High Reliability, Energy Efficient

- Torque

- 24.6 Nm

- Ambient Temperature

- -20 to +50 C

- Rated Frequency

- 50 Hz

- Current Type

- AC

- Pressure

- Standard Atmospheric

- Product Type

- ABB Electric Motor

- Output Power

- 3.7 kW

- Frequency (MHz)

- 50 Hz

- Protect Feature

- Totally Enclosed Fan Cooled (TEFC)

- Phase

- Three Phase

- Speed

- 1440 RPM

- Power

- 5 HP

- Color

- Grey

- Dimension (L*W*H)

- 400 x 220 x 280 mm

- Weight

- 36 kg

- Shaft Diameter

- 28 mm

- Mounting Type

- Foot Mounted (B3)

- IP Rating

- IP55

- Lubrication

- Grease Lubricated

- Frame Size

- 112M

- Duty Type

- S1 (Continuous Duty)

- Altitude Limit

- Up to 1000 m ASL

- Service Factor

- 1.15

- Construction Type

- Cast Iron Body

- Direction of Rotation

- Bi-directional

- Rotor Construction

- Aluminium Die Cast

- Efficiency at Full Load

- 87.6%

- Vibration Level

- Within Permissible Limit

- Insulation Class

- Class F

ABB ELECTRIC MOTOR Trade Information

- Minimum Order Quantity

- 05 Pieces

- Supply Ability

- 05 Pieces Per Month

- Delivery Time

- 05 Days

About ABB ELECTRIC MOTOR

ABB is a multinational corporation headquartered in Switzerland that specializes in the production of industrial technology, including electric motors. ABB electric motors are widely used in industrial, commercial, and residential applications around the world.

ABB offers a wide range of electric motor products, including low and high voltage motors, synchronous and asynchronous motors, and permanent magnet motors. Their motors are designed to operate in a wide range of environments and applications, from harsh industrial environments to clean room applications.

ABB electric motors are known for their high efficiency and reliability, which helps to reduce energy consumption and maintenance costs. ABB also offers a range of motor control solutions, such as variable frequency drives and soft starters, that are designed to improve the performance and efficiency of their motors.

In addition to electric motors, ABB also offers a range of other industrial products and services, including automation and control systems, power distribution equipment, and robotics. Their products and services are used in a wide range of industries, including oil and gas, mining, power generation, and transportation.

Overall, ABB is a leading provider of electric motor technology and related products and services, and their products are trusted by customers around the world for their quality, reliability, and performance.

Durability and Reliability

Constructed with a robust cast iron body and aluminium die cast rotor, the ABB Electric Motor ensures lasting durability even under demanding conditions. Its deep groove ball bearings and grease lubrication system further enhance reliability and require minimal maintenance over time.

Energy Efficiency and Performance

Rated at IE2 efficiency, this motor achieves 87.6% full load efficiency and 24.6 Nm torque, promoting reduced energy consumption and cost savings. The continuous duty (S1) operation with bi-directional rotation and fan-cooled design delivers consistent and high performance in industrial applications.

Environmental Adaptability

The motor operates efficiently in ambient temperatures from -20C to +50C and at altitudes up to 1000 meters above sea level. Its dust-proof, IP55-sealed enclosure and Totally Enclosed Fan Cooled (TEFC) feature make it suitable for varied industrial environments, ensuring safety and extended lifespan.

FAQ's of ABB ELECTRIC MOTOR:

Q: How does the ABB Electric Motor benefit industrial applications?

A: This ABB motor offers high reliability, low maintenance requirements, and robust construction, making it ideal for demanding industrial uses that require continuous operation (S1) and superior energy efficiency (IE2).Q: What is the recommended process for starting the ABB Electric Motor?

A: The motor is designed for Direct On Line (DOL) starting, which provides straightforward installation and ensures smooth startup under full rated voltage for three-phase AC applications.Q: Where can the ABB Electric Motor be installed for optimal performance?

A: It can be installed in a wide range of environments, thanks to its IP55 dust-proof rating and TEFC enclosure. Suitable for locations up to 1000 meters altitude and ambient temperatures ranging from -20C to +50C.Q: When should maintenance be performed on this ABB motor?

A: Routine inspection and lubrication are recommended per manufacturer guidelines; the motor's grease lubrication and deep groove ball bearings ensure extended time between services and low overall maintenance.Q: What usage applications are best suited for the ABB Electric Motor?

A: Its continuous duty rating, bi-directional capability, and standard foot-mounted (B3) design make it ideal for pumps, compressors, fans, conveyors, and general industrial machinery.Q: What are the benefits of the Totally Enclosed Fan Cooled (TEFC) protection feature?

A: TEFC provides effective cooling while preventing dust and contaminants from entering the motor, enhancing lifespan, safety, and reliability especially in harsh industrial settings.Q: How does the efficiency rating of IE2 impact operational cost?

A: IE2 classification ensures reduced energy consumption during operation, resulting in lower electricity costs and minimized environmental impact over the motor's lifespan.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Kirloskar Electric Motor/ Crompton Electric Motor Category

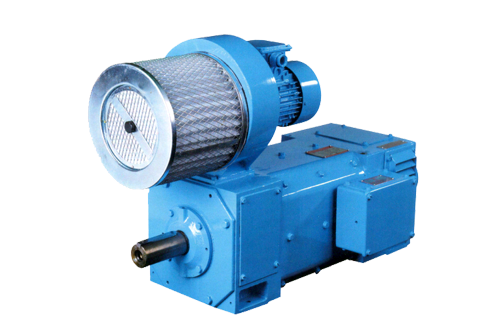

Electric DC Motor

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Phase : Three Phase

Voltage : 380 Volt (v)

Power : 200 Watt (w)

Protect Feature : Waterproof

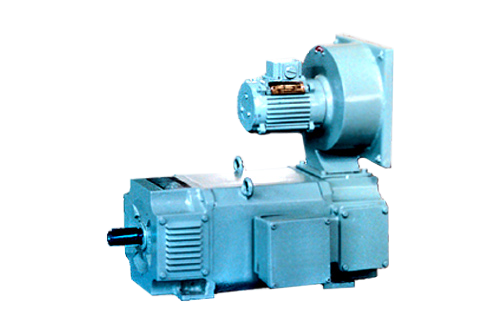

DC Motor

Price 15000 INR / Unit

Minimum Order Quantity : 1 Unit

Phase : Three Phase

Voltage : 380 Volt (v)

Power : 200 Watt (w)

Protect Feature : Waterproof

"We are only dealing in North India."

Send Inquiry

Send Inquiry

Call Me Free

Call Me Free